Blogs By Cyclotron: Welding Automation

Cyclotron:

A revolution in the world of welding

We established our presence in the market in 2018, specializing in metal working with a focus on manufacturing professional-grade welding automation products

Welding Table: A complete Guide

A welding table is a flat and stable surface at the waist height of a welder which operates like a workbench for welding. It provides clamping surface for any parts to be welded and fabricated instead of welding it on ground.

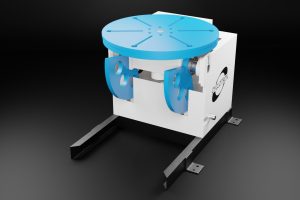

Cyclotron Welding Positioners

Welding Positioners are mechanical devices that hold a work part and provides flexibility for the welder to rotate the workpiece as per the requirement of the welder. It allows the operator to work at a certain angle providing a consistent surface to weld.

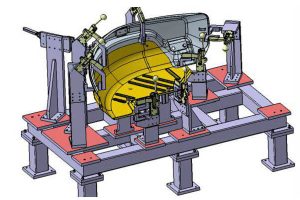

Robotic welding fixtures

In robotic welding, the post-weld cleanup and spatter removal are greatly reduced, decreasing the downtime between the projects.

Modular welding fixtures vs traditional

The modular welding fixture comes with a flat surface table comprising machined holes to precisely hold clamps and components for seamless welding operations.

Types of Welding fixtures

4 types of welding fixtures are Gas, arc, resistance & laser welding fixtures.

The main purpose of a fixture is to locate, support and hold the workpiece in position firmly to obtain a precise product from a process.

Sielding gases for welding

While welding any metal or a component, the high temperatures produced during the process melts the material and a molten metal weld pool is formed.

Design of welding fixtures

For high production or complex objects fixturing, some additional arrangements are required when compared to simple fixturing

Welding table top material

Mild Steel: IS 2062 is the most commonly used material in Welding Table Top. Carbon Steel is also one of the options for the welding table tops, along with Cast Iron & Stainless steel.

What is a checking fixture?

A checking fixture is a quality assurance tool used in industries to check for the quality of components with complex shapes.