BIW Lines (Welding)

Manual spot welding fixture

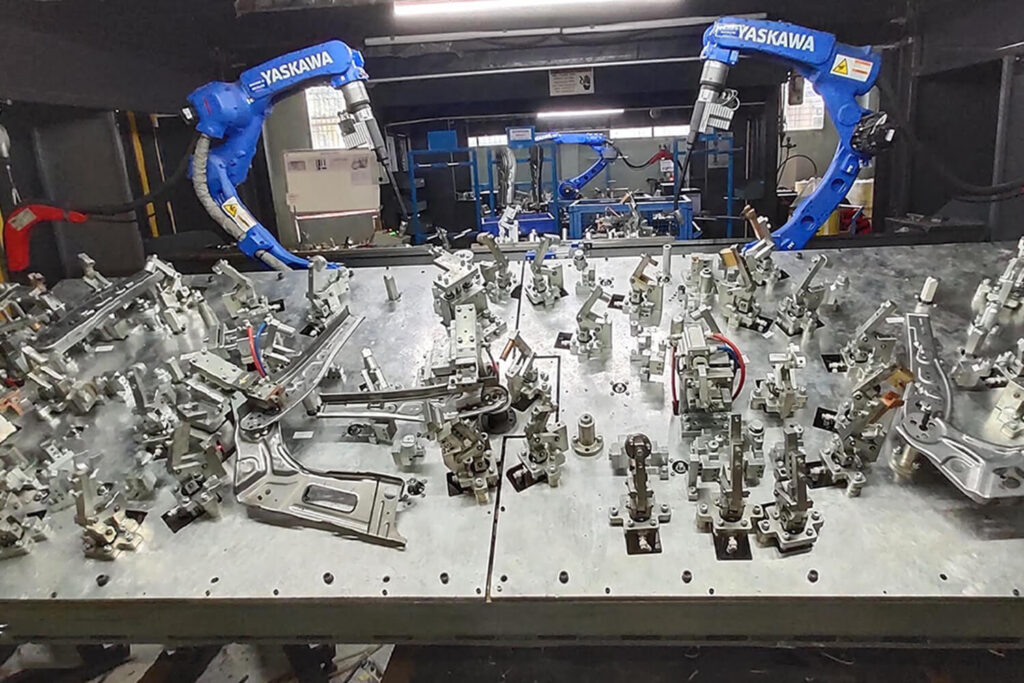

robotic cell for automotive seat

BIW welding FIXTURE

We at CYCLOTRON Automation are a BIW lines manufacturer from Pune, India. We provide Robotic/manual spot welding fixtures for automotive, commercial vehicles, and heavy truck industries. We manufacture industrial robotic and manual body-in-white (BIW) welding lines for use in the assembly lines for automobiles, truck chassis. Robots made for welding heavy-duty areas with high levels of precision are designed for this purpose. As part of our service, we also train your crew on how to use these robotic fixture machines.

We have in-house manufacturing facilities for all our products, thus eliminating delays and ensuring precision.

WHAT IS BIW?

The Body-in-White is a phase of automobile manufacturing where the car body frame is welded to its parts except chassis subassemblies, moving parts and trims like electronics, handles, etc. in short it is the car sheet metal welded structure.

The BIW constitutes some part of the car’s weight. Hence it has a significant effect on the factors like vibrations, noise, crashworthiness of the vehicle and how the vehicle performs.

There are two types of BIW:

Body on Frame Construction:

The body is mounted on a different frame than the chassis while the wheels and suspension are mounted on the chassis. This type is commonly found in trucks, buses or utility vehicles.

Monocoque Construction

Unlike the first type, in the Monocoque construction, the chassis is inbuilt with BIW. Wheels and suspensions are mounted on the BIW itself without the requirement of any separate chassis. This type is used in passenger cars and a few utility vehicles. Here frame itself acts as the main load-carrying member.

Properties of BIW

- It should possess high tensile strength and high stiffness of all kinds like bending, torsional, both static and dynamic.

- Safety should be the top priority while manufacturing a BIW. The safety of the vehicle body and its occupants should be considered.

- It should protect the occupants from any noise, vibration and harshness (NVH) that occur during the vehicle functioning by absorbing them.

- The BIW material of construction should be corrosion-resistant and lightweight as it contributes to some weight of the vehicle.

- It should be easy to design and eco-friendly taking into consideration the increased risk of environmental concerns.

Of all the materials, aluminium and steel are suitable materials for manufacture. While steel provides high strength and low cost, aluminium is preferred for its lightweight reducing the weight of the vehicle.

Recently, CFRP (carbon fibre reinforced plastics) have taken over both the above materials for their high suitability as a BIW material. It is observed that CFRP possessed lower density and higher specific strength when compared to others. The cost of the vehicle is greatly reduced due to the selection of CFRP material. The material due to its lower density reduces the vehicle’s weight thereby decreasing the load on the batteries. This property of CFRP is highly useful for longer battery life and thus it works best for an electric vehicle.

BIW Lines

We know that automation is taking over in almost every industry. Welding demands a high level of accuracy and precision for the final product to execute its functionality. Hence, robots and other techniques are incorporated into the welding industry. One such arrangement is the BIW weld line. The robot and manual BIW weld lines are constructed for the optimal functioning of assembly lines of automobiles, trucks etc.

Need a BIW Welding fixture? Contact us