Welding Positioners

Welding Positioners

Welding positioners are essential tools in the welding industry, specifically designed to hold and rotate workpieces at the desired angles for optimal welding. These devices enhance productivity, improve weld quality, and ensure the safety of welders. This guide will delve into the various types of welding positioners, their applications, and the benefits they offer.

Get Best Welding Positioners

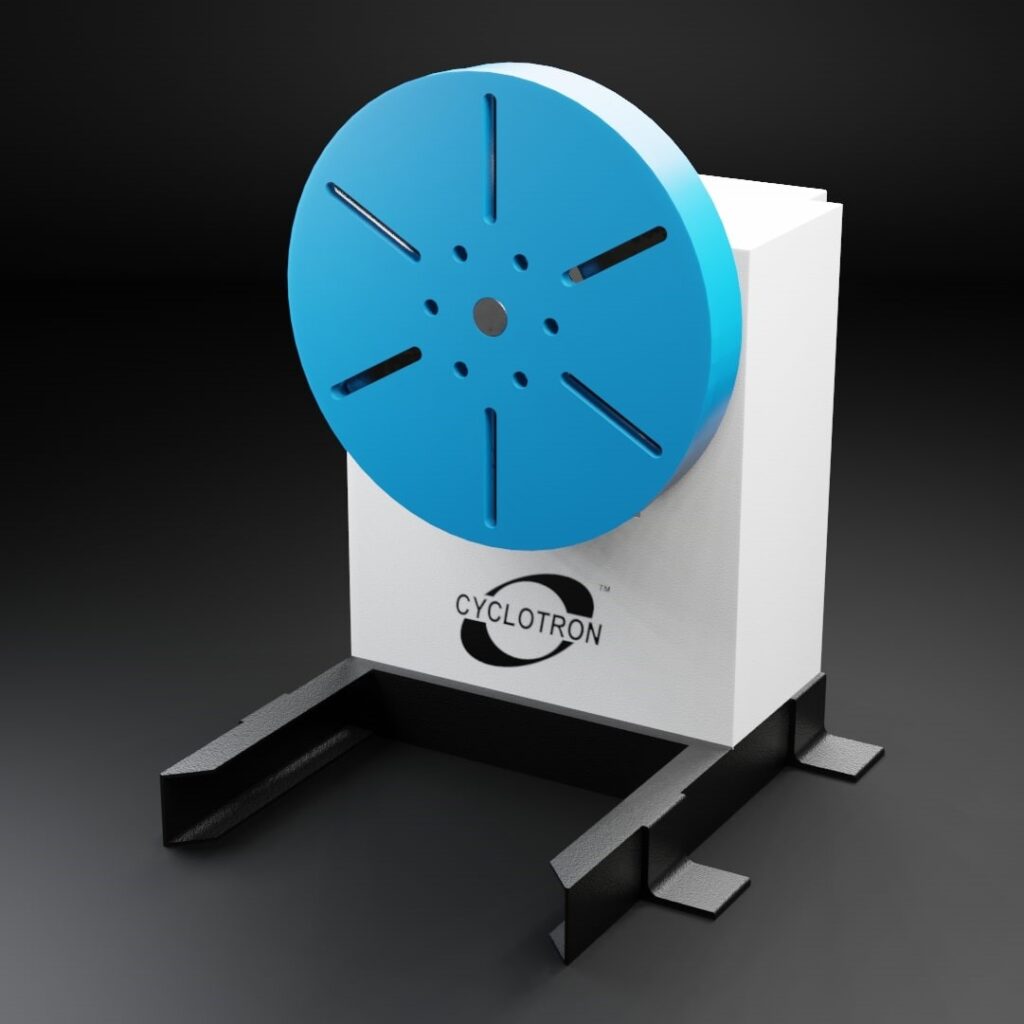

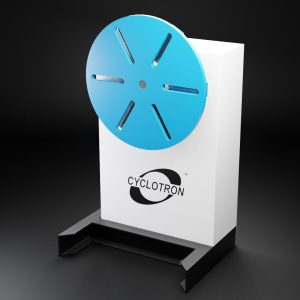

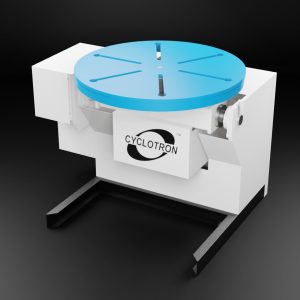

Cyclotron is the leading manufacturer of Welding Positioner in India.

Our Engineered weld positioners are designed to align the job to the best position for down hand welding, whether it is a non-circular job or a rotating circular job. The structure of our adjustable welding positioners is carefully configured to allow for rotation and angular tilting of the table, ensuring optimal results.

Benefits of Welding Positioners

- Improve quality: By securely holding workpieces in optimal positions, these tools lead to higher-quality welds.

- Cost Efficiency: By decreasing labor costs associated with manual adjustments, welding positioners contribute to overall savings in production costs.

- Improved productivity: Automation minimizes the need for frequent manual repositioning, allowing for faster job completion.

- Reduced Fatique: Operators can focus on tasks without constantly moving heavy equipment, minimizing physical strain.

- Versatality: With various types available, welding positioners can accommodate various materials and projects.

Get Best Welding Positioners by Cyclotron

12 Tons Welding Positioner

12 Tons Welding Positioner

4 Tons Welding Positioner

Universal Welding Positioner

Features of Cyclotron Welding Positioners

-

Weight Capacity:

Cyclotron provides Welding positioners starting from as small as 25 kgs to upto 25 Tons in weight capacity (From 25 kgs to 25,000 Kgs). -

Adjustable rotation speed:

The speed of the positioner can be adjusted based on the requirement which goes upto 0.5 RPM. Digital Speed indicator to monitor the speed of the machine. -

Heavy Duty Structure:

Cyclotron provides a heavy duty structure for welding positioners and hence it provides stability for the complete structure.

-

Imported Gearbox:

Cyclotron uses an imported gearbox of Bonvario for better quality of the product. Back-lash free gearbox for rotation and tilting -

Variable frequency drive:

Heavy duty Variable Frequency Drive (VFD) for continuous operation without overheating and tripping -

Ergonomically designed:

We create the most comfortable and safe products for humans to work around. - Rotation speed: 0.04-0.4, 0.05-0.5 rpm (Variable)

Looking for a reliable Welding positioner manufacturer?

Contact us at +91 9881217196

OR

Fill this form and our representative will get back to you.

Need a Welding Positioner?

We at Cyclotron Robotics and Automation Pvt. Ltd. manufacture all types of welding positioners as per your requirement.

Things to remember while working on the Welding Positioners

1. Positioner to be placed on an even surface

Make sure that the welding positioner unit is mounted on an even flat surface. Any unevenness on the surface causes the workpiece to fall in the middle of the operation which could pose a severe threat to the welder.

2. The importance of Centre of Gravity

Picking up the right positioner for your work part should not only depend on the size and weight of the weldment but also the centre of gravity and its distance from the positioning device. The CG is the point on which all the weight of the weldment is concentrated. As the distance of CG increases from the positioning device, more torque is applied to the positioner. Also, adding parts to the positioner changes the centre of gravity which should be kept in mind by the welder while making changes.

3. Specifications of the positioner

The table revolves around a multi-speed electric motor that can be hand-controlled or foot-controlled. Thus the positioner motor and controller is to be selected based on the parameters with which the desired welding operation is performed. As the positioner specifications guide the motor and control choice, it is necessary for the welder to check the specifications for both vertical and horizontal loading to ensure that the positioner has the capacity to handle the maximum load without failure.

4. Ensure accurate attachment of the weldment

As the weldment is physically attached to the positioner, you should make sure that it is attached accurately without any misalignment or improper attachment. The latest positioners come with slots that allow the workpiece to be bolted to the face.

5. Ground current to be connected to the Positioner

During the operation, connect the ground current to the positioner. The ground current is transferred from the table and into the chassis thus eliminating the need to replace the welding clamp frequently. Also, improper grounding can damage the electrical parts and produce poor weld deposits. The positioner should be compatible with the current produced during the operation and ensure that all grounding cables are firmly secured.

Need a Welding Positioner?

We at Cyclotron Robotics and Automation Pvt. Ltd. manufacture all types of welding positioners as per your requirement.

Customers List

Choose the Right Welding Positioner for Your Needs

Welding positioners are transformative tools that can revolutionize your welding operations. Do you want to upgrade your equipment? Or start a welding business? These devices enhance weld quality, increase efficiency, and reduce labor costs. This results in higher productivity, flawless welds, and improved customer satisfaction, driving greater profits.

Ready to find the best welding positioners for sale in India? At Cyclotron Automation, we provide technologically advanced, durable welding positioners that elevate Indian standards to a world-class level. Our intuitive interface allows operators to quickly learn and master the use of welding positioners. As a result, they work with more confidence, experience less fatigue, and maintain greater focus—ultimately boosting weld quality.

Upgrade today and weld with precision and efficiency!

Need a Welding Positioner?

We at Cyclotron Robotics and Automation Pvt. Ltd. manufacture all types of welding positioners as per your requirement.