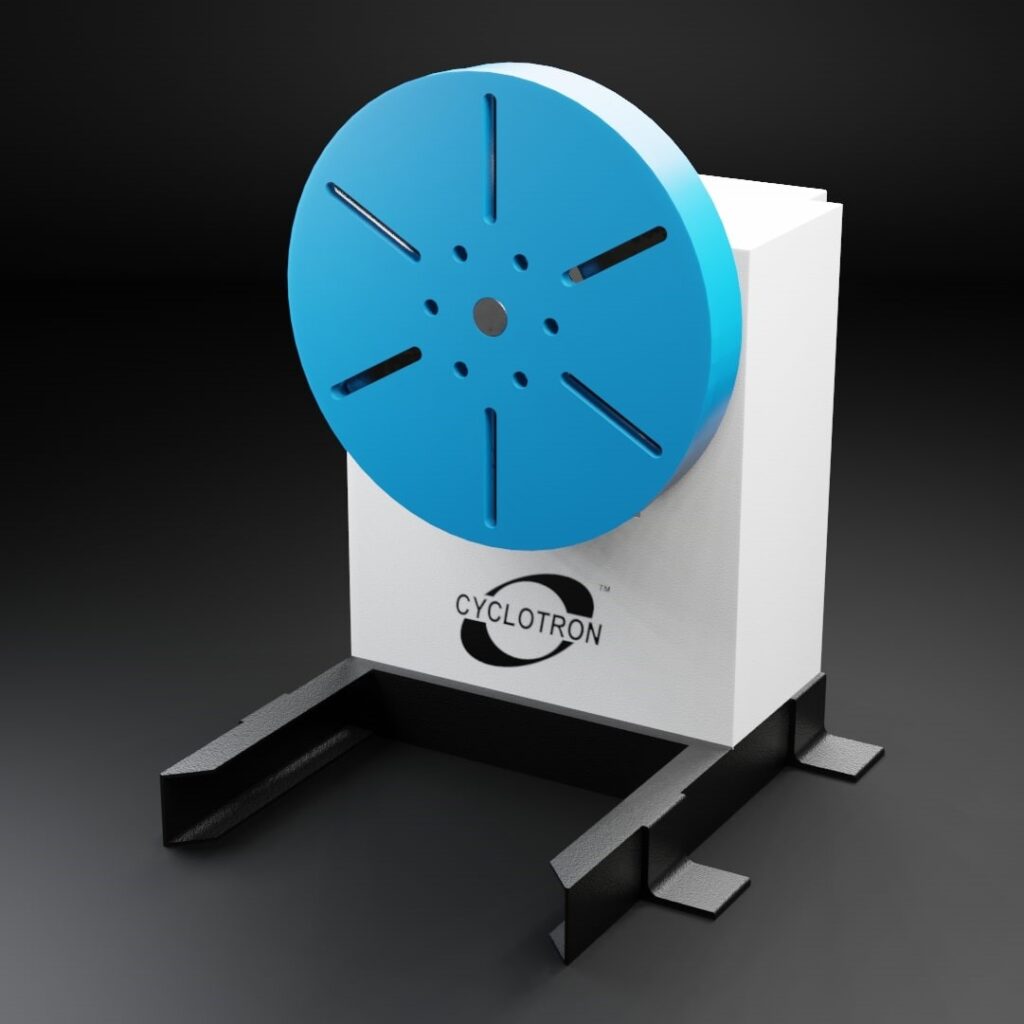

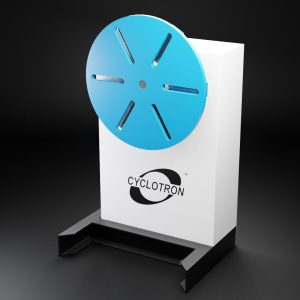

Welding Manipulator by Cyclotron

Welding Manipulators

Welding manipulators, engineered by Cyclotron Automation, are innovative devices designed to position and rotate workpieces, enhancing welding efficiency and accuracy.

These manipulators enable welders to maintain optimal positions during operations, ensuring consistent welding surfaces and minimizing physical strain during complex jobs

Welding Manipulator Manufacturer

Cyclotron Automation specializes in manufacturing a diverse range of welding manipulators, including rotary tables, robotic turntables, and customized weld positioners.

We specialise in providing high-quality welding manipulators to meet the needs of various industries. As a reliable manufacturer, exporter and supplier of welding turntables based in India, we take pride in our commitment to delivering innovative and effective solutions to our customers.

What is a Welding Manipulator?

Consider performing a manual weld without a manipulator—shifting and rotating a heavy workpiece can be both exhausting and time-consuming. Welding manipulators solve this. It consumes time and energy and the operator gets tired easily reducing the productivity and quality of the weld. Some arrangement is necessary to accommodate easy movement of the workpiece so that the welder’s job is eased and a lot of time is saved. This is where the welding positioners come into the picture.

Get Best Welding Manipulators

Cyclotron is the leading manufacturer of Welding Manipulators in India.

Our Engineered weld positioners are designed to align the job to the best position for down hand welding, whether it is a non-circular job or a rotating circular job. The structure of our adjustable welding positioners is carefully configured to allow for rotation and angular tilting of the table, ensuring optimal results.

Significance of Welding Manipulators

- Enhanced Weld Quality: Precise positioning by manipulators ensures controlled welds, reducing manual errors and delivering superior finished products.

- Improved speed: By Using a welding positioner, it is possible to make welds in flat or downhand position which can improve the speed, it can be better as well as cheaper. When the posiioner is not used the welds are commonly deposited as relatively lower rate.

- Improved productivity: The use of positioner can eliminated the need for the operator to hold the arc manually, which increases the productivity of the process.

Get Best Welding Manipulators by Cyclotron

12 Tons Welding Positioner

12 Tons Welding Positioner

4 Tons Welding Positioner

Universal Welding Positioner

Features of Cyclotron Welding Manipulators

-

Weight Capacity:

Our welding positioners accommodate loads from 25 kg to 50 tons, tailored to handle everything from light parts to heavy industrial workpieces. -

Adjustable rotation speed:

Adjustable speeds of up to 0.5 RPM allow precise control, with integrated digital indicators providing seamless monitoring during operations. -

Heavy Duty Structure:

Cyclotron provides a heavy duty structure for welding positioners and hence it provides stability for the complete structure.

-

Imported Gearbox:

Cyclotron uses an imported gearbox of Bonvario for better quality of the product. Back-lash free gearbox for rotation and tilting -

Variable frequency drive:

Heavy duty Variable Frequency Drive (VFD) for continuous operation without overheating and tripping -

Ergonomically designed:

We create the most comfortable and safe products for humans to work around. - Rotation speed: 0.04-0.4, 0.05-0.5 rpm (Variable)

Need high-quality welding manipulators tailored to your needs?

Contact Cyclotron at +91 9881217196 / 7057997990 or submit your details, and our team will assist you promptly.

Headstock Tailstock Manipulator Drawings

- Structure of the part: The structure of the welding part will decide what type of welding positioner is needed for the process. The Dimensions along with the weight and the centre of gravity of the part the most important factors which decides the type of positioner required

- Welding quality: Based on your welding operation, the welding positioner should be able to weld the part without any vertical welding or overhead welding and maintain the quality of your welding

- Rotation speed: Depending on the welding beaded size and the time taken for it, the rotation speed of the welding positioner needs to be decided. Also if you need a constant speed or adjustable speed.

- Ergonomic design: The design of the positioner should be operator friendly. It should be compact and with a proper height required for the operator, should also consider all the safety instructions.

Working Principle of Welding Manipulator

Cyclotron welding manipulators enable precise positioning by creating rotational planes that simplify welding operations. They accommodate various tooling configurations.. The type of materials that are to be held by welding positioners depends on the positioner’s ability to hold them. They include pipes and fittings, tanks and vessels, non-uniform workpieces etc.

Why use a Welding Manipulator?

1. Improve Safety:

The traditional material handling equipment depend on cranes, chains, trucks, ad forks etc. They are used to pull, move, drag or position the heavy work parts and their fixtures in position for the welding operation. Their actions are uncontrolled and can be extremely dangerous to the operators and the welders if the equipment falls or swing due to any improper functioning of cranes or trucks. Extra costs are incurred due to the damage that occurred to the equipment and workplace. Sometimes human lives are in danger too. In the presence of welding positioners, such hazards are avoided as they eliminate the need for chains, hoists to lift and rotate the weldments. The positioners firmly position the weldment and can raise them or rotate up to a certain height

Enhance Safety & Efficiency: Welding manipulators reduce risks, boost production rates, and ensure accurate, high-quality welds with improved visibility and precision.

2. Improve throughput

They reduce the unproductive time while keeping the welders safe and also improving the quality and productivity of the welding. A considerable amount of time is consumed while working with cranes. It requires labour to control the movements of the crane and position it accurately. The positioner helps the operator to quickly orient the crane and positon it accurately saving the labours hours and increasing the arc time of the welder.

3. They improve weld quality and visibility

The work part is to be oriented in the best possible angle to produce optimal quality welding. The manufacturers suggest that a joint is to be placed in 1F (Flat welding) and 2F (Horizontal welding) positions for better penetration and deposition rate. In 1F position welding, the joint is held at 45 degrees inclination for best deposition rate. In 2F welding, the joint is held at 90 degrees for utmost penetration. The positioners ensure maximum weld quality as they firmly hold the joint in place at the comfortable reach of the welder with better visibility.

It provides a stable working surface at any desired angle to the operator. Hence the accuracy of welding is greatly improved. They can be equipped in compact spaces where there is limited room on the production floor. Once connected to a power source, a welding positioner act as a semi-automatic machine which enhances the welding speed and improves productivity.

Welding manipulators are integral in industries like automotive manufacturing, heavy equipment assembly, and structural fabrication, delivering seamless welding results

Need a Welding Manipulator?

We at Cyclotron Robotics and Automation Pvt. Ltd. manufacture all types of welding positioners as per your requirement.

Things to remember while working on the Welding Manipulators

1. Positioner to be placed on an even surface

Make sure that the welding positioner unit is mounted on an even flat surface. Any unevenness on the surface causes the workpiece to fall in the middle of the operation which could pose a severe threat to the welder.

2. The importance of Centre of Gravity

Picking up the right positioner for your work part should not only depend on the size and weight of the weldment but also the centre of gravity and its distance from the positioning device. The CG is the point on which all the weight of the weldment is concentrated. As the distance of CG increases from the positioning device, more torque is applied to the positioner. Also, adding parts to the positioner changes the centre of gravity which should be kept in mind by the welder while making changes.

3. Specifications of the positioner

The table revolves around a multi-speed electric motor that can be hand-controlled or foot-controlled. Thus the positioner motor and controller is to be selected based on the parameters with which the desired welding operation is performed. As the positioner specifications guide the motor and control choice, it is necessary for the welder to check the specifications for both vertical and horizontal loading to ensure that the positioner has the capacity to handle the maximum load without failure.

4. Ensure accurate attachment of the weldment

As the weldment is physically attached to the positioner, you should make sure that it is attached accurately without any misalignment or improper attachment. The latest positioners come with slots that allow the workpiece to be bolted to the face.

5. Ground current to be connected to the Positioner

During the operation, connect the ground current to the positioner. The ground current is transferred from the table and into the chassis thus eliminating the need to replace the welding clamp frequently. Also, improper grounding can damage the electrical parts and produce poor weld deposits. The positioner should be compatible with the current produced during the operation and ensure that all grounding cables are firmly secured.

Need a Welding Manipulator?

We at Cyclotron Robotics and Automation Pvt. Ltd. manufacture all types of welding positioners as per your requirement.

Customers List

Types of Welding Manipulators

1. Two-axis Manipulators:

Also known as tilt/turn positioners, they provide flexibility in moving workpieces in horizontal and vertical axes directions. These are used in various pipe applications like flanges and elbows etc.

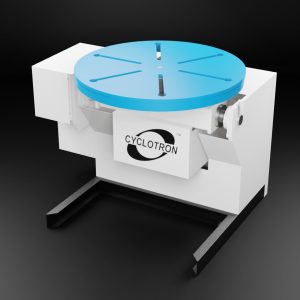

2. Welding Turntables:

The welding turntables are used in applications where the workpiece is required to rotate about a vertical axis. The rotary welding turntables provide accurate positioning in the flat or horizontal position. They are used for welding, flame cutting and other machining applications.

3. Turning Rolls:

They are used for positioning heavier cylindrical work parts like pressure vessels and multisided poles.

4. Headstock and Tailstock Manipulators

A Headstock is used for rotating shorter workpieces horizontally whereas, for larger and heavier work parts, the support tailstock is required additionally. They offer maximum flexibility while lifting and rotating massive work parts like trailer frames etc.

5. Pipe Welding Positioners

Their presence is advantageous while welding pipes, shafts, and elbows etc. Besides the welding turntables, the pipe welding positioners are mainly used for positioning and orienting the workpieces with large offset loads. From pipe spooling to chassis components, they are useful in positioning complex work parts too

6. Rotary Welding Positioners

With the rotary welding positioners, welding of round objects has never been this easy and efficient. A variable speed control box lets you choose between different speeds suitable for the operation. These positioners are mainly used in precision welding applications.

7. Gripper welding chucks:

It is used to hold the complex shaped metal parts between the headstock and tailstocks to allow welding operation. They are designed to withstand the adverse conditions of the industry.

Conclusion

Thoroughly evaluate your project needs before selecting a welding manipulator. Cyclotron offers both brand-new and cost-effective options for diverse industrial tasks. But these are most commonly used for mounting welding equipment, rotary positioning, mounting of various parts of assemblies etc. Study your requirements thoroughly. Based on this, you can choose between a variety of welding positioners. Both new and used welding positioners are available in the market. You can also rent a welding positioner as per your necessity.

Need a Welding Manipulators?

We at Cyclotron Robotics and Automation Pvt. Ltd. manufacture all types of welding positioners as per your requirement.