Welding Positioners

Welding Positioners : A Complete Guide

Welding positioners are essential tools in the welding industry, specifically designed to hold and rotate workpieces at the desired angles for optimal welding. These devices enhance productivity, improve weld quality, and ensure the safety of welders. This guide will delve into the various types of welding positioners, their applications, and the benefits they offer.

What Is a Welding Positioner?

A welding positioner is a specialized mechanical device that securely holds and manipulates workpieces during welding operations. Its primary functions include:

- Secure Holding: It ensures that parts are positioned correctly to facilitate high-quality welds.

- Rotation and Alignment: The positioner rotates workpieces and maintains them in the desired alignment and orientation.

- Consistent Surface: It provides a stable surface for welding, allowing operators to work efficiently without frequent adjustments.

Types of Welding Positioners

The welding positioning equipment can be categorized based on their functionality:

1. Manual Welding Positioners

As the name says, manual welding positioners are tools that require welders to adjust the workpiece manually. They are ideal for small parts and are commonly used in workshops where automation is unnecessary. Their simplicity leads to lower maintenance requirements.

2. Motorized Welding Positioners

The motorized welding position equipment features motorized rotation and tilting mechanisms, making them suitable for precision welding tasks. They help reduce welder fatigue by automating repetitive movements, making them popular in industries such as aerospace and automotive.

3. Headstock Tailstock Welding Positioners

Designed for long and heavy workpieces, these positioners consist of a headstock for rotational movement and a tailstock to stabilize the other end of the workpiece. This type of tool can be operated manually or motorized, depending on the job requirements.

4. Multi-axis Positioners

These versatile positioners allow movement along multiple axes, including rotation, tilting, and height adjustments. This flexibility enables welders to access complex geometries easily, making them ideal for industries like shipbuilding and robotics.

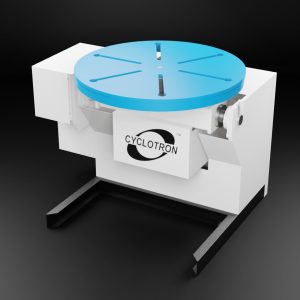

5. Turntable Positioners

Equipped with a rotating platform, turntable positioners are designed to hold circular components such as rings and flanges. They facilitate smooth, continuous movement for uniform welds.

6. Rotary Table Positioners

A rotary table positioner is built to handle large applications. They provide better control over the rotation of workpieces and are commonly used in industries like oil and gas, where precise welding of long components is crucial.

7. Adjustable Height Positioners

As their name suggests, these positioners allow vertical adjustments of workpieces during welding. This feature enhances comfort during long sessions and is particularly useful in construction and fabrication settings.

Applications of Welding Positioners

- Oil and Gas Sector

The oil and gas industry deals with the construction and maintenance of pipelines, large storage tanks, and pressure vessels. Welding positioners provide sturdy support for heavy components, enabling continuous and precise welding, especially for cylindrical parts. This enhances weld quality and improves operator safety by reducing manual handling.

2. Automotive Industry

Welding positioners play a crucial role in automated and manual welding processes in the automotive sector. They ensure precise alignment of metal components, enabling seamless welding of chassis, frames, and exhaust systems while improving efficiency in mass production.

3. Aerospace Industry

Aerospace components are exposed to extreme temperatures and harsh environmental conditions, requiring precision welding for structural integrity. Welding positioners aid in fabricating aircraft frames, engine components, and landing gear, ensuring high-strength, defect-free welds.

4. Robotic Welding Systems

In automated welding systems, welding positioners firmly hold workpieces and optimize their positioning, reducing the need for manual adjustments. This enhances repeatability, accuracy, and production speed, making them ideal for high-volume manufacturing operations.

5. Heavy Equipment & Construction Sector

Construction and heavy equipment industries rely on rotating and tilting mechanisms for welding large workpieces. Welding positioners provide a stable base, allowing operators to access critical weld areas that are difficult to reach, improving both efficiency and safety in bridge construction, steel structures, and heavy machinery fabrication.

6. Defense and Military Applications

Precision welding is crucial in the defense industry, where components must withstand extreme conditions. Welding positioners are used to fabricate armored vehicles, assemble weapon components, and construct military-grade infrastructure, ensuring durability and structural integrity.

Choose the Right Welding Positioner for Your Needs

Welding positioners are transformative tools that can revolutionize your welding operations. Do you want to upgrade your equipment? Or start a welding business? These devices enhance weld quality, increase efficiency, and reduce labor costs. This results in higher productivity, flawless welds, and improved customer satisfaction, driving greater profits.

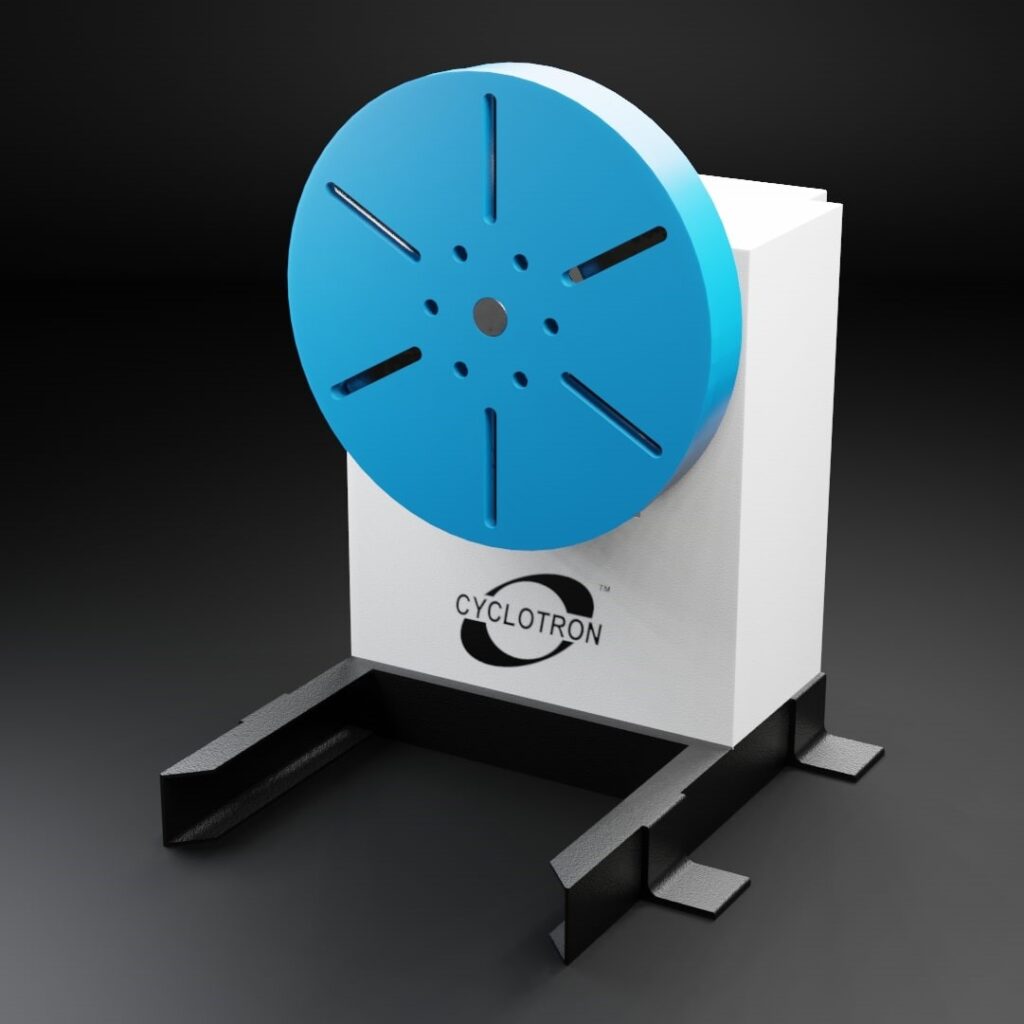

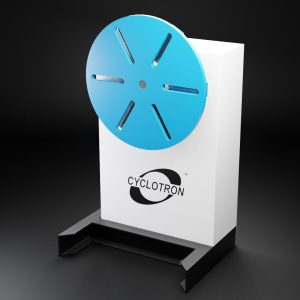

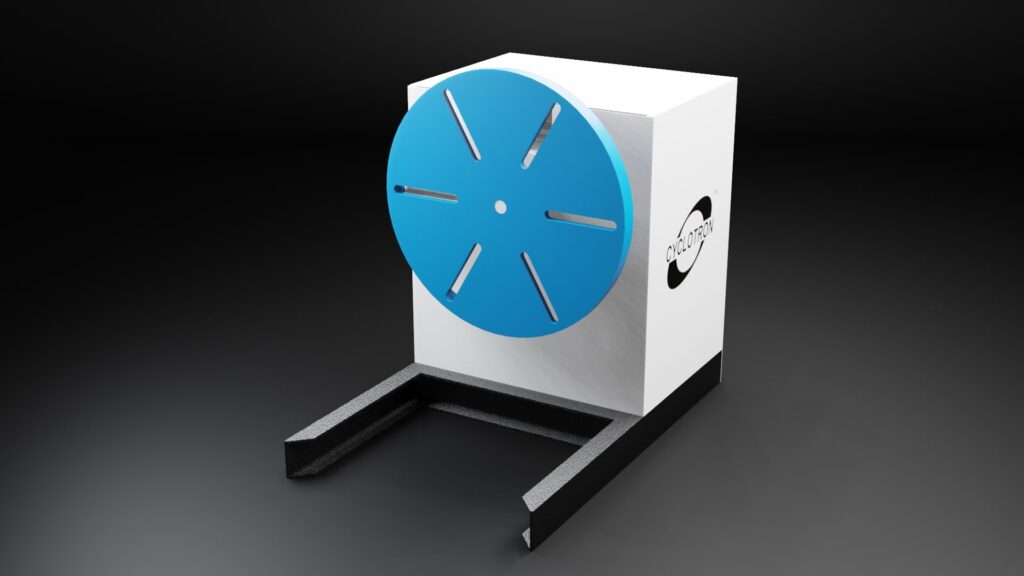

Ready to find the best welding positioners for sale in India? At Cyclotron Automation, we provide technologically advanced, durable welding positioners that elevate Indian standards to a world-class level. Our intuitive interface allows operators to quickly learn and master the use of welding positioners. As a result, they work with more confidence, experience less fatigue, and maintain greater focus—ultimately boosting weld quality.

Upgrade today and weld with precision and efficiency!

Looking for a reliable Welding Positioner?

Contact us at +91 9881217196

OR

Fill this form and our representative will get back to you.

Countries we Export to