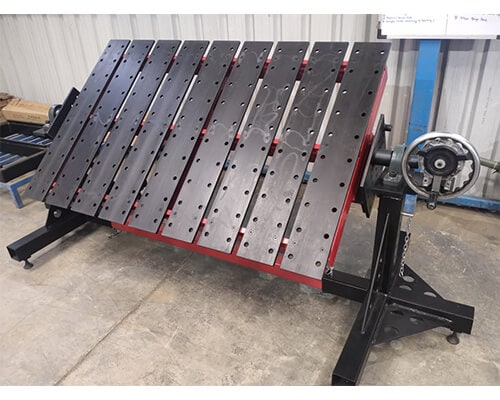

Rotary Welding Table By Cyclotron

Cyclotron is the Leading Manufacturer & exporter of Rotary Welding tables. We manufacture, supply & export all kinds of Rotary Modular welding tables according to the industrial needs.

Our major focus is on innovation and development of Modular fixturing solutions.

Rotary tables for welding

Rotary welding tables have a total 360° rotation of the table surface.

They Come in two variants

1. Manual Rotary Welding table

2. Motorised Rotary Welding table

- Hole diameter: 16mm

- Hole center distance: 50mm

- Top Plate thickness: 16 mm

- Flatness: 0.3/1000 mm

- Loading Capacity: 1 to 7 ton

- Top Plate Material– Steel IS 2062

- Frame Material– Steel IS 2062

- Surface coating– Powder coated

- Top Plate– Standard/ Nitrided

Looking for a reliable Welding Tables Manufacturer?

Contact us at +91 9881217196

OR

Fill this form and our representative will get back to you.

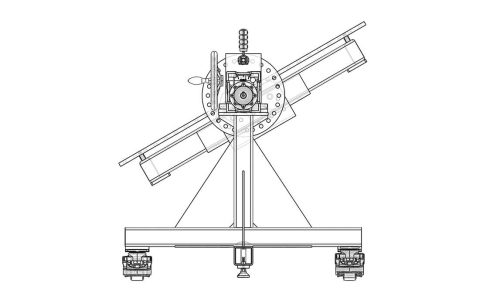

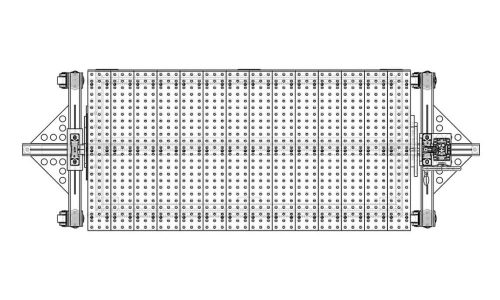

2D Drawings of Rotary Welding Table

Front View

Side View ( Manual table)

Top View

Side View ( Motorised table)

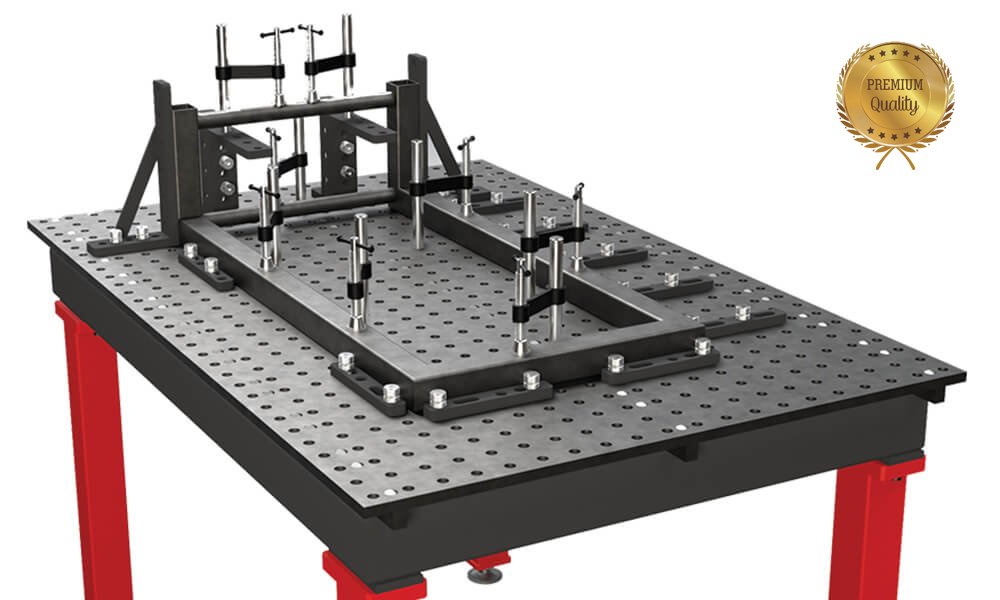

Features of Cyclotron Modular Rotary Welding tables

-

Manual & Motorised

Cyclotron Rotary Welding tables comes with Manual as well as Rotary options. Manual tables can have maximum capacity upto 3 tons and Motorised has max capacity upto 7 tons -

Hardness:

The top plate of Cyclotron welding tables are Nitrided for spatter proof surface and for durability of your welding products. -

Grid system:

The table has a worktop with D16/D28 system bores in a 50 mm x 50 mm grid resulting in greater clamping options as compared to 100mm x 100mm grid.

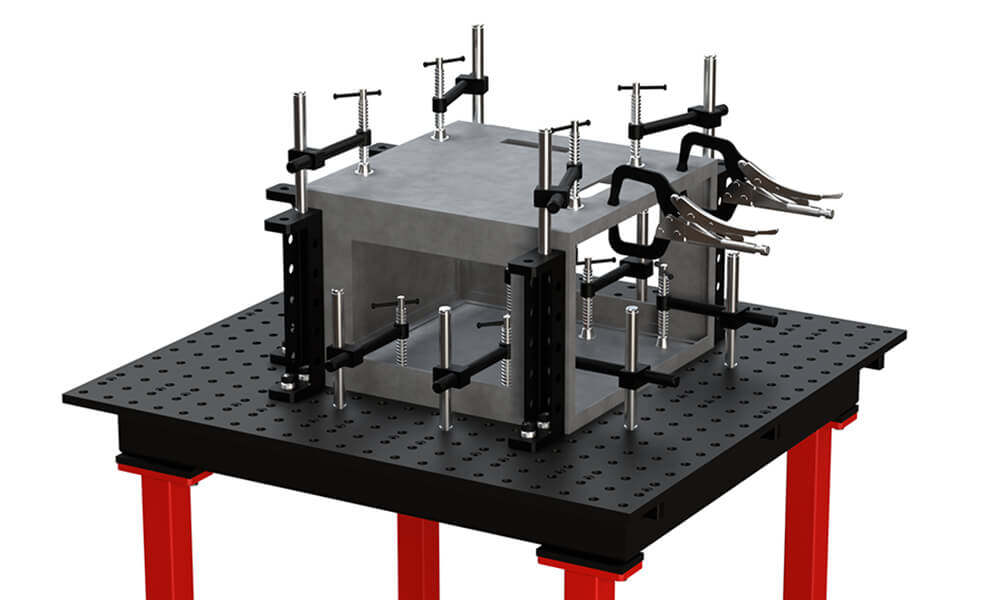

Rotary Welding table clamps

Cyclotron is the Leading Manufacturer, supplier & exporter of Welding table clamps. Fixture clamps for welding have various applications including height improvement, angle constraints, stopping & pushing a welding part, clamping with the table, and many more

Customers List

About Cyclotron Welding tables

CYCLOTRON is India’s Fastest growing manufacturer of modular welding table.

CYCLOTRON is on the mission of providing the complete range of World’s Finest and Boldest modular welding tables at affordable prices.

The innovation in design, manufacturing and inspection of the product is the true reason for its optimum cost without compromising the quality of the product.

OUR Team of EXPERTS is working for YOU to improve your fabrication process

Why Choose Cyclotron Rotary Welding tables?

- High Engineered: Cyclotron has designed the Rotary tables with high precision. While traditional flat tables may be suitable, for projects intricate welding tasks require precision in every dimension.

- Manual & Motorised Cyclotron Rotary Welding tables comes with Manual as well as Rotary options. Manual tables can have maximum capacity upto 3 tons and Motorised has max capacity upto 7 tons.

- Highly Versatile: Whether you’re working on a small scale project or tackling scale industrial applications these tables prove to be highly versatile because of the high accuracy of building.

- Modular design: The adjustable fixtures and modular design of these rotary tables can accommodate workpieces of sizes and shapes. This adaptability is crucial in todays diverse welding landscape, where professionals often face a range of projects.

- Time Saving: In the welding industry time is money and investing in a rotary welding table significantly contributes to time efficiency. The precision provided by these tables minimizes the time spent on adjustments.

- Cost Saving: Additionally by reducing rework requirements businesses can experience cost savings when utilizing welding tables—making them an intelligent investment choice, for optimizing welding processes.

Rotary Welding table top surface

-

Nitrided surface:

Cyclotron gives a nitrided surface improving surface properties of metal and corrosion resistance, and increase the fatigue strength.

-

Grid System:

3d Modular welding table has a worktop with D16 system bores in a 50 mm x 50 mm grid resulting in greater clamping options as compared to 100mm x 100mm grid . -

Improved clamping options:

Further improving the expansion and clamping options by 3 hole drilling pattern on the side plates with D16 system bores in 50 x 50mm.

Countries we Export to