Robotic Welding system manufacturer in India

We at Cyclotron Automations are manufacturers of Robotic Welding system , robotic weld positioners, Welding turntables, robotic welding turntables in India.

We specialise in providing high-quality robotic welding systems to meet the needs of various industries. As a reliable manufacturer, exporter and supplier of robotic welding systems based in India, we take pride in our commitment to delivering innovative and effective solutions to our customers.

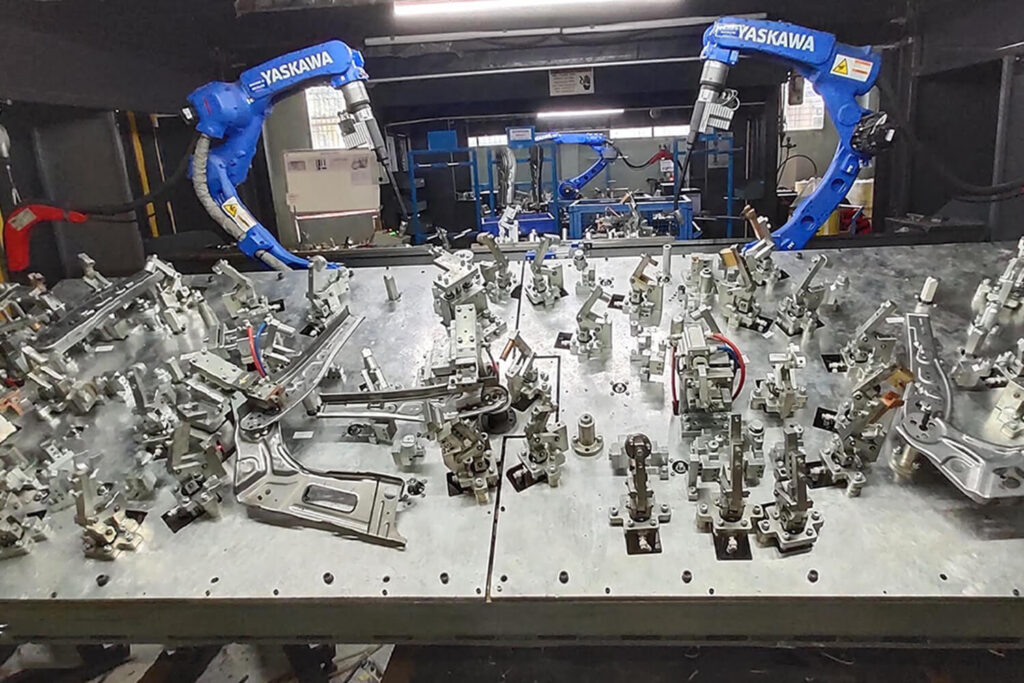

Robotic welding system fixture 1

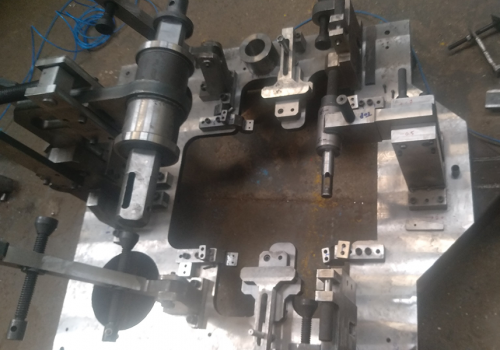

Robotic welding system fixture 2

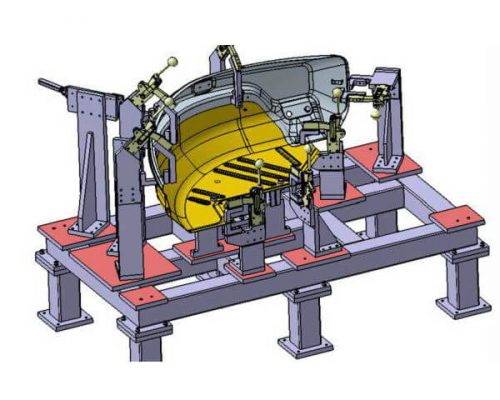

Robotic welding system fixture 3

Robotic Welding Fixtures Manufacturer

Loader Bucket Welding fixture

BIW Welding fixture

Axle Support Welding fixture

BIW Welding fixture

Bucket loader welding fixture

Welding fixture

Designing and developing a robotic welding fixture

We examine your product as well as the other options to position your parts accurately. Before a product is welded, it may be necessary to integrate a specific functionality. Other factors play a part as well, such as the number of products, the ease of use of the ergonomic options, or the expected costs.

When long welds are required or if the maximum casting is required, the fixture should have a cooling function. A similar situation occurs when the material buckles when exposed to heat.

We are involved early on in the product development process when customers are developing ideas. As a result, smart solutions can be developed. In many cases, simplifying, accelerating, and reducing the production process is possible by including welding in the development stage.

5 Advantages of Robotic welding systems

- Enhanced Precision and Quality: Unlike manual welding robotic welding performs consistent output with each weld.

- Cost effective operation: Although the initial investment in robotic welding might be substantial, but it will always give better returns from long term point of view.

- Increased production speed: Robots can work at a faster rate than humans increasing the overall speed of the production and thus giving better ROI for business.

- Improved safety: Human interaction with hazardous welding fumes is reduced. robots can take the dangerous tasks for humans.

- Consistent output: Robotic welding gives you a very high repeatability of a particular product which is not possible in manual welding.