Welding Positioner Manufacturer in Pune

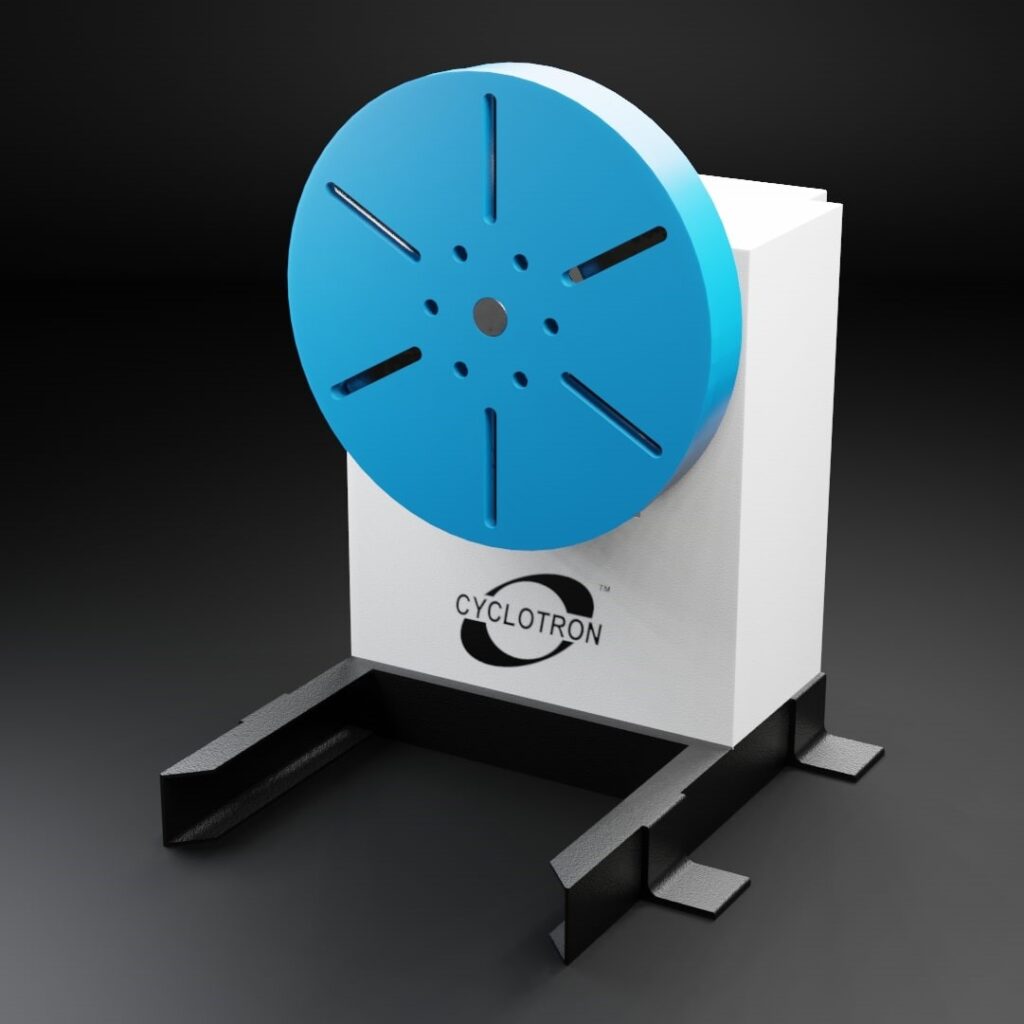

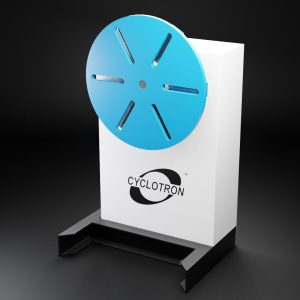

We at Cyclotron Automations are manufacturers of Welding positioners, weld positioners, Welding turntables, Rotary tables for welding, robotic welding turntables in Pune.

We specialise in providing high-quality welding positioners to meet the needs of various industries. As a reliable manufacturer, exporter and supplier of welding turntables based in India, we take pride in our commitment to delivering innovative and effective solutions to our customers.

Get Best Welding Positioners in Pune

Cyclotron is the leading manufacturer of Welding Positioner from Pune.

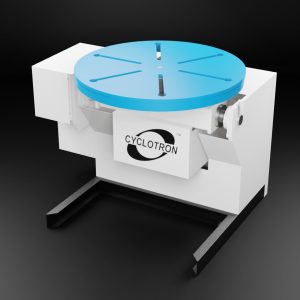

Our Engineered weld positioners are designed to align the job to the best position for down hand welding, whether it is a non-circular job or a rotating circular job. The structure of our adjustable welding positioners is carefully configured to allow for rotation and angular tilting of the table, ensuring optimal results.

Get Best Welding Positioners in Pune

12 Tons Welding Positioner

12 Tons Welding Positioner

4 Tons Welding Positioner

Universal Welding Positioner

Features of Cyclotron Welding Positioners

-

Weight Capacity:

Cyclotron provides Welding positioners starting from as small as 25 kgs to upto 25 Tons in weight capacity (From 25 kgs to 25,000 Kgs). -

Adjustable rotation speed:

The speed of the positioner can be adjusted based on the requirement which goes upto 0.5 RPM. Digital Speed indicator to monitor the speed of the machine. -

Heavy Duty Structure:

Cyclotron provides a heavy duty structure for welding positioners and hence it provides stability for the complete structure.

-

Imported Gearbox:

Cyclotron uses an imported gearbox of Bonvario for better quality of the product. Back-lash free gearbox for rotation and tilting -

Variable frequency drive:

Heavy duty Variable Frequency Drive (VFD) for continuous operation without overheating and tripping -

Ergonomically designed:

We create the most comfortable and safe products for humans to work around. - Rotation speed: 0.04-0.4, 0.05-0.5 rpm (Variable)

6 Tons Welding Positioner in Pune of Truck Trailers

Looking for a reliable Welding positioner manufacturer?

Contact us at +91 9881217196

OR

Fill this form and our representative will get back to you.

Things to look while buying a Welding positioner in Pune

- Structure of the part: The structure of the welding part will decide what type of welding positioner is needed for the process. The Dimensions along with the weight and the centre of gravity of the part the most important factors which decides the type of positioner required

- Welding quality: Based on your welding operation, the welding positioner should be able to weld the part without any vertical welding or overhead welding and maintain the quality of your welding

- Rotation speed: Depending on the welding beaded size and the time taken for it, the rotation speed of the welding positioner needs to be decided. Also if you need a constant speed or adjustable speed.

- Ergonomic design: The design of the positioner should be operator friendly. It should be compact and with a proper height required for the operator, should also consider all the safety instructions.

Our Customer list

4 Tons Cyclotron Positioner in Pune

Significance of Welding Positioners in Pune

- Improve quality: The positioned parts look great and has a better quality because of the controlled welding and less manual stuff involved.

- Improved speed: By Using a welding positioner, it is possible to make welds in flat or downhand position which can improve the speed, it can be better as well as cheaper. When the posiioner is not used the welds are commonly deposited as relatively lower rate.

- Improved productivity: The use of positioner can eliminated the need for the operator to hold the arc manually, which increases the productivity of the process.

5 Types of Welding Positioners in Pune

- Two-Axis Positioners: Also known as tilt/turn positioners, these enable workpiece movement in both horizontal and vertical axis directions They are used primarily in welding applications such as pipe, flange, and elbow.

- Welding turntables: Welding turntables are used in applications where the workpiece needs to be rotated around a vertical axis. They provide precise positioning on a flat or horizontal surface and are useful in welding, flame cutting, and other machining applications.

- Rotary Welding Positioners: These positioners are primarily used for precision welding applications involving round objects. They have a variable speed box that allows you to choose the right speeds for the job.

- Headstock and Tailstock Positioners: Headstocks are used to turn small workstations up, while larger and heavier jobs additionally require a supporting post These positioners offer greater flexibility when giving work large such as a trailer frame on and converted.

- Pipe Welding Positioners: These positioners are especially for positioning and orienting large offset weighted workpieces, such as pipes, shafts, elbows and are also useful for placing complex workpieces, such as pipe spooling and chassis components.